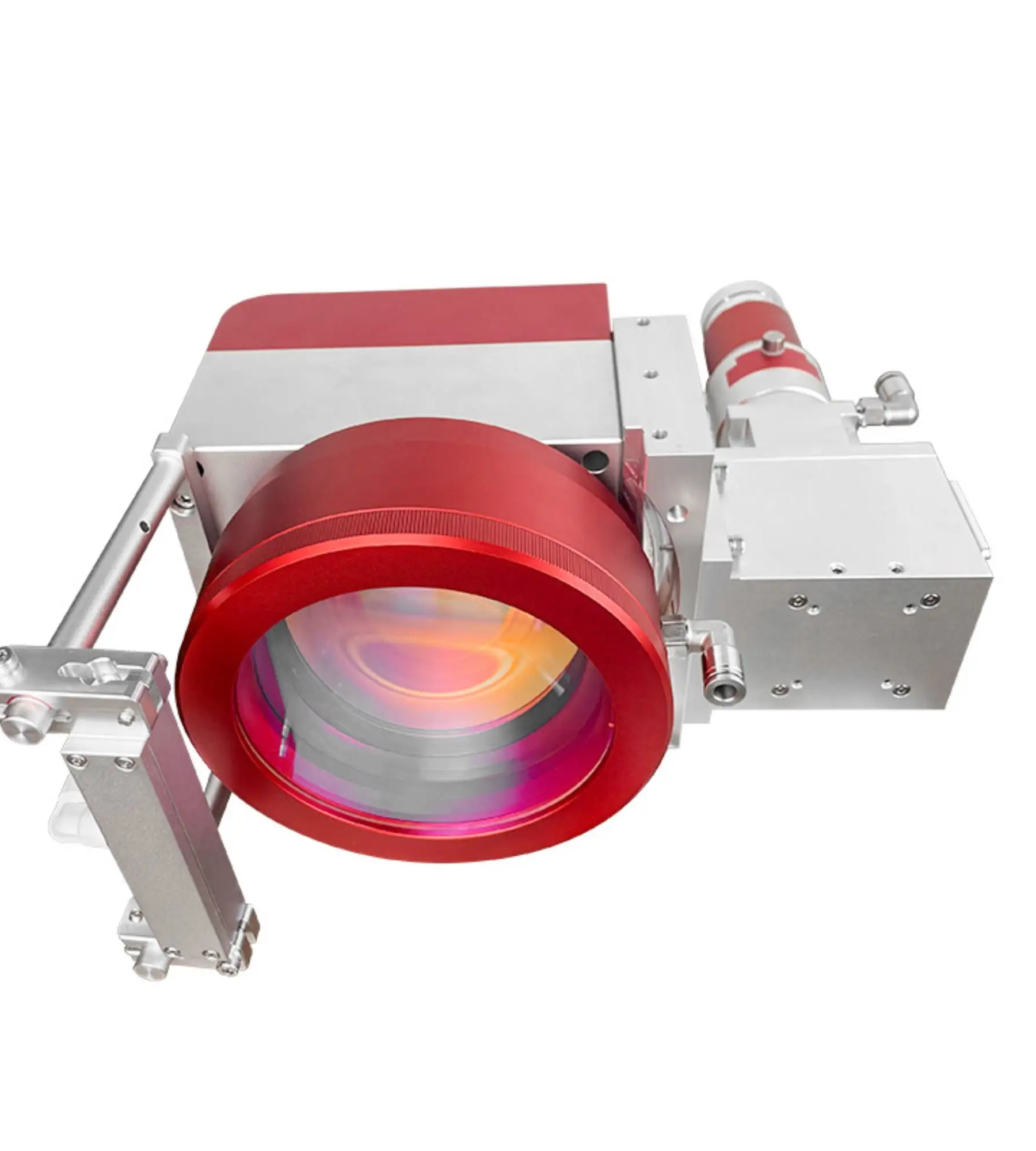

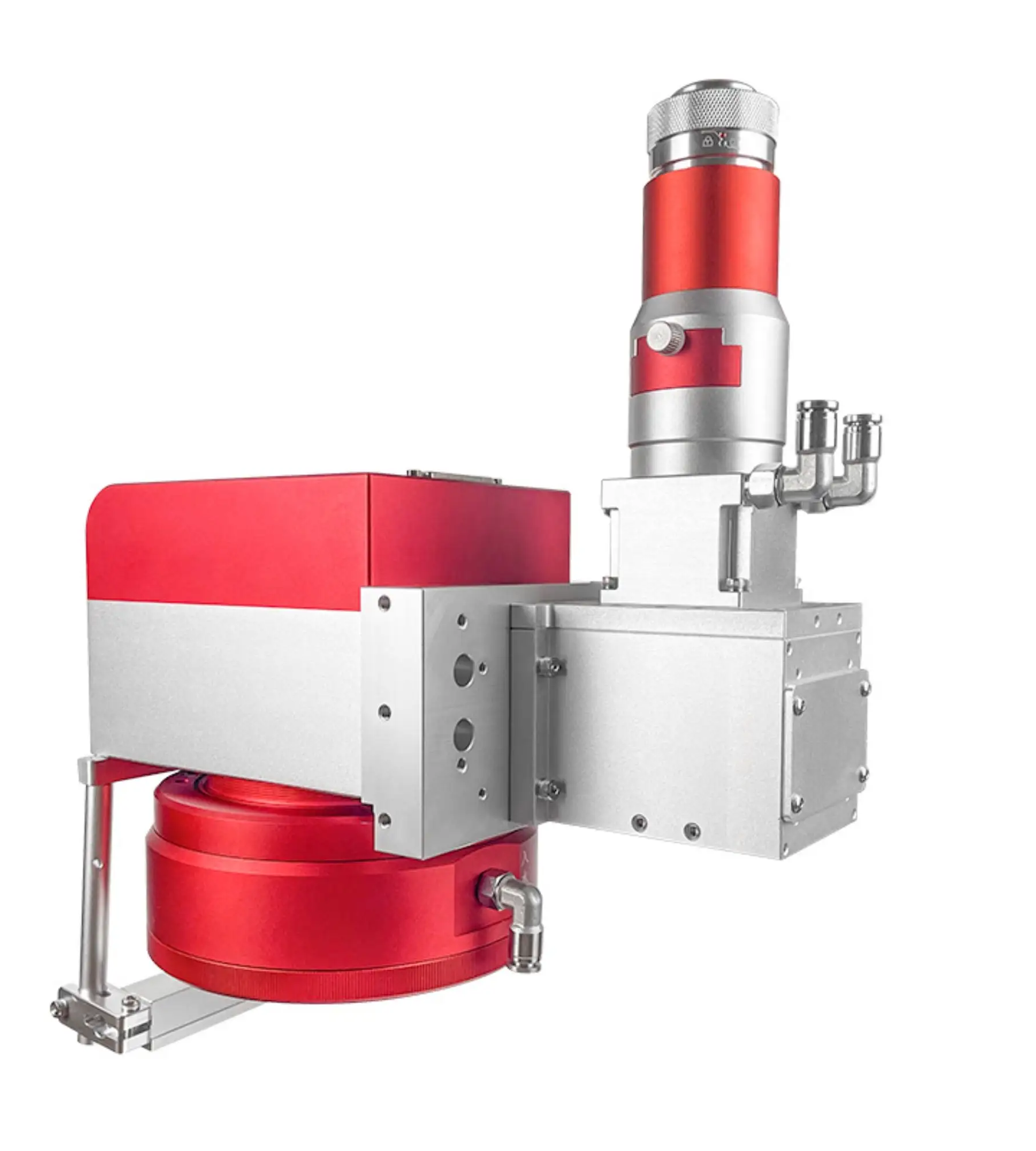

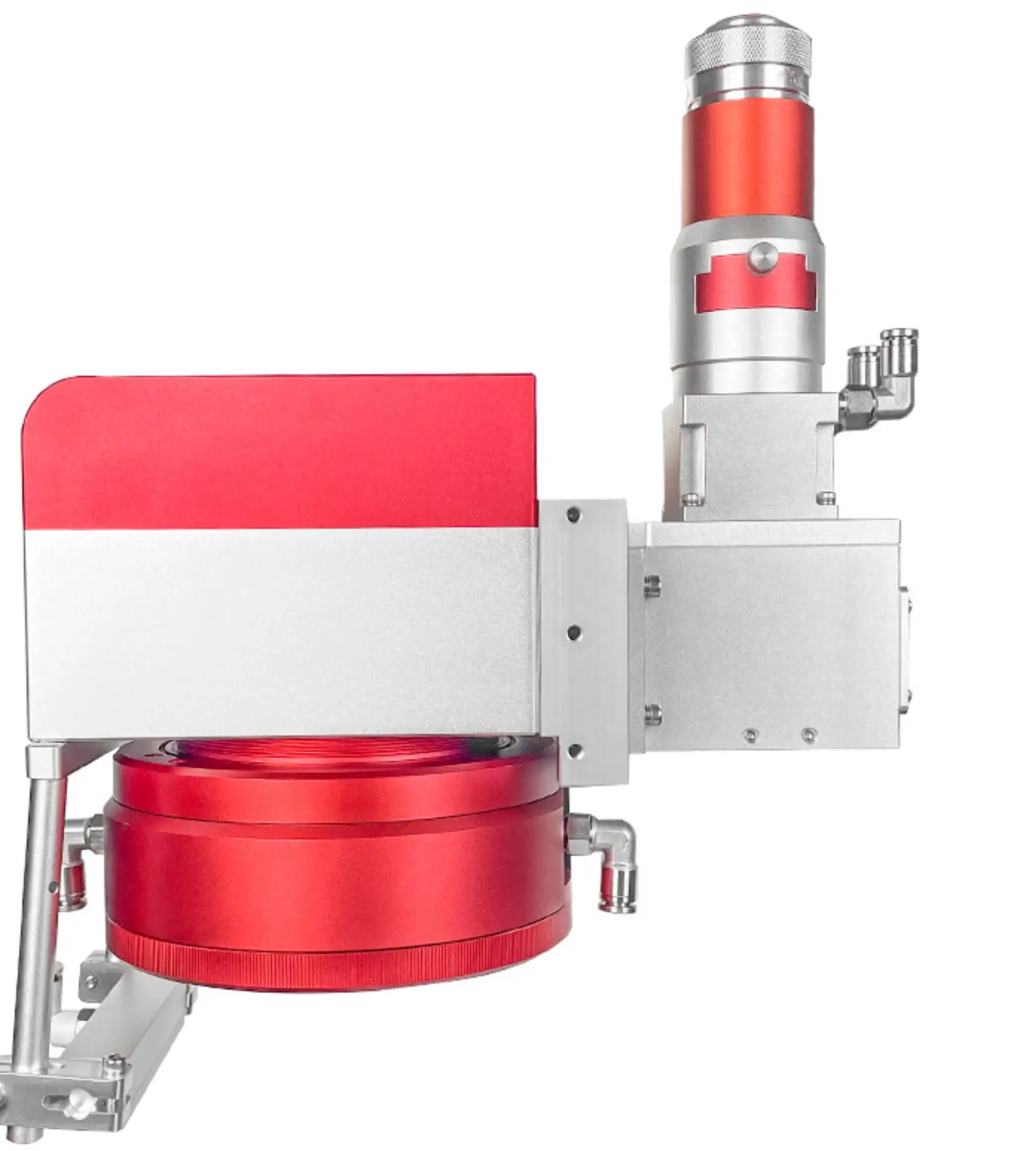

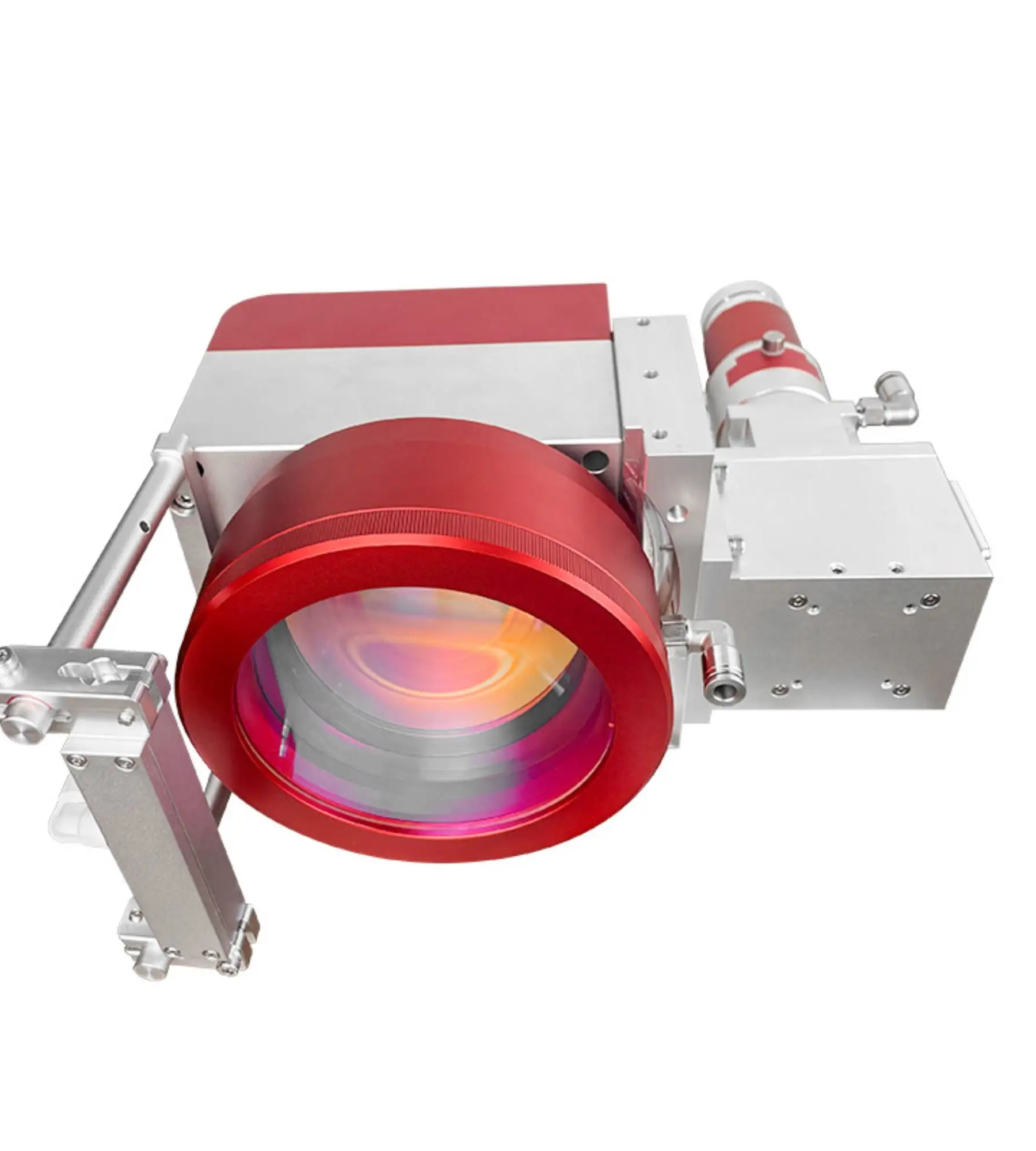

Zbtk's platform swing welding machine is a testament to versatility, capable of handling a diverse array of welding applications with ease. Whether you're welding small, intricate components or large, flat surfaces, our machine can adapt to your specific needs with adjustable welding parameters and a wide range of focal distances. The non-contact nature of swing welding also means that delicate or sensitive materials can be welded without the risk of physical damage, making Zbtk's machine ideal for industries such as aerospace engineering or medical device manufacturing. Trust Zbtk for a platform swing welding machine that offers limitless possibilities in customization and application.

In industrial welding, Zbtk’s platform swing welding machine is an embodiment of precision and steadiness. Our machine comes with the most advanced swing welding technology that exists today; this allows it to make complete even welds on various materials with unprecedented accuracy. Whether you need to bond large structural components together or perform intricate welds, each of our platform swings ensures perfect execution which will enhance your brand’s professional image. It has a strong structure and easy-to-use interface such that it can be integrated into any production line without affecting efficiency negatively thus increasing output while reducing downtimes at workstations where these machines are used consecutively for long hours. If you want a platform swing welding machine which will not let you down in terms of quality or performance; then go for ours because we always deliver beyond customer expectations.

The platform swing welding machine from Zbtk is a versatile piece of equipment that can handle many different types of welding. Our machine can adjust to any size job, whether it be small intricate pieces or large flat surface areas. This is possible because we have adjustable welding settings and can work with various focal distances. Another advantage of using our non-contact swing welder is its ability to not harm fragile materials during the process; this makes us perfect for industries like aerospace engineering where they deal with such delicate things or making medical devices which need very careful handling. Get a platform swing welding machine at Zbtk and you will never run out of ways to use it!

The platform swing welding machine by Zbtk is an example of highly developed technology in the welding industry. We can appreciate how powerful swing welding technology is by looking at our ability to focus accurately during welding without affecting the surrounding areas. This feature is especially useful for industries like pharmaceuticals, healthcare and food processing where hygiene is very important. Besides preventing contamination it also guarantees that surface are free from dangerous bacteria or any other microorganism which can cause harm.Zbtk ensures all its clients that their methods are both efficient and secure when they use platform swing welding machines.

Sustainability is one of the main concerns at Zbtk considering the current manufacturing situation. The platform swing welding machine we offer as an option for traditional welding processes is eco-friendly because it does not waste much energy and also reduces waste produced. This equipment utilizes swing welding technology which enables it to create deep clean welds without any harmful emissions or dangerous wastes. Such a system does not only save the environment but also ensures that workers have a safe working area around them. Using Zbtk’s platform swing welding machine will enable you keep being environmentally friendly while providing well-done welded items to clients who value green practices too.

Ultra-fast scanning for bulk marking.

Portable power for on-site marking.

Eco-safe rust removal for bulk cleaning.

Durable, precise marking for volume production.

Zbtk's platform swing welding is a specialized welding method that utilizes a platform with a swinging motion to evenly distribute heat and create a consistent weld bead. The process involves positioning the workpiece on the platform, which then swings back and forth under the welding torch, ensuring a uniform weld and reducing the likelihood of defects such as cold laps or incomplete fusion.

Zbtk's platform swing welding system is designed to weld a wide range of materials, including mild steel, stainless steel, aluminum, and other common metals. It is particularly effective at welding thick sections and large workpieces, as the swinging motion helps to distribute heat more evenly and prevent warping or distortion.

Yes, Zbtk's platform swing welding is an eco-friendly welding option. It uses less energy compared to traditional welding methods due to the even heat distribution, which also results in less smoke and fumes. Additionally, the system's design promotes better material utilization, reducing waste and scrap.

Compared to manual welding or other automated welding systems, Zbtk's platform swing welding offers several advantages. It is faster, more consistent, and requires less human intervention. The swinging motion of the platform provides a deeper and more uniform weld than can be achieved with simple stationary welding methods.

Absolutely. Zbtk is committed to ensuring that our clients can fully utilize our platform swing welding system. We offer comprehensive training on how to operate the system effectively and safely, as well as ongoing technical support to address any questions or issues that may arise. Our goal is to empower our clients to achieve optimal results with our swing welding technology.