A revolution in the accuracy of the laser industry has been brought about by technology that controls laser beams’ direction extremely accurately at high speed using galvanometers. Commonly found in manufacturing, medicine and research industries; these devices can quickly scan and position beams thereby saving time as well as increasing productivity. For example, in medical use such as LASIK eye surgeries or skin treatments where invasiveness should be minimized with less scarring; they are useful also for controlling fluorescence induced by lasers during research together with spectroscopy experiments because they provide exactness. This means that even if various types or systems are used for lasers, one can still employ Galvo scanner since it is versatile enough to adapt them all which makes its applications wide-ranging indeed. It cools them down too much so they don’t overheat while being robust enough not only durable but reliable too — this should be considered an essential tool by any industry depending on lasers.

Ultra-fast scanning for bulk marking.

Portable power for on-site marking.

Eco-safe rust removal for bulk cleaning.

Durable, precise marking for volume production.

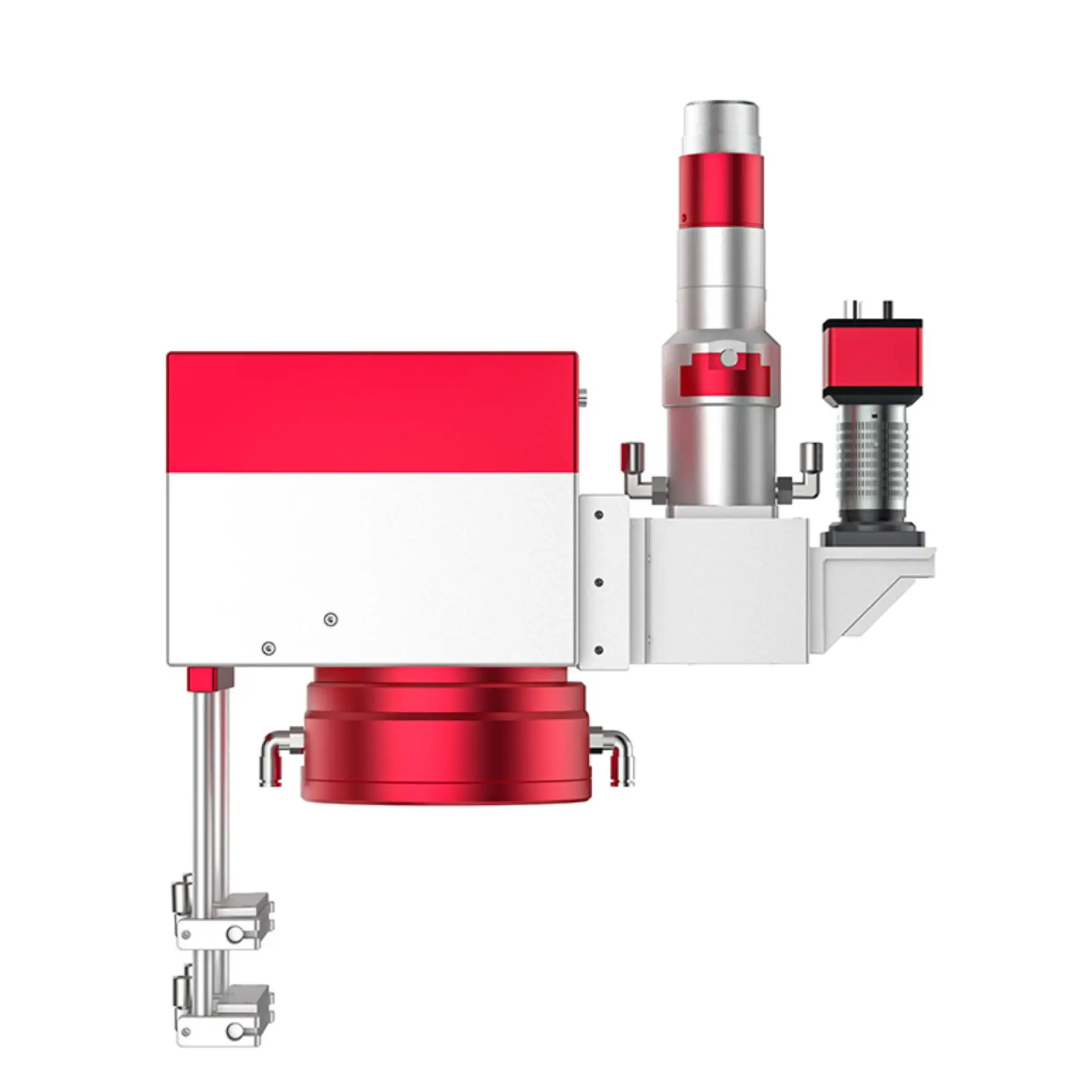

Galvanometer technology involves the use of an electromechanical device called a galvanometer to control the angle of a laser beam with precision. The galvanometer contains a small mirror attached to a motor that moves in response to an electrical current. By adjusting the current, the angle of the mirror—and consequently the direction of the laser beam—can be precisely controlled. This allows for accurate and rapid positioning of the laser beam, making it ideal for applications such as laser engraving, cutting, marking, and medical procedures.

The primary advantages of galvanometer technology in industrial applications include:

In the medical field, galvanometer technology offers several benefits:

Galvanometer technology is compatible with a wide range of laser types, including:

When integrating galvanometer technology into existing systems, consider the following: