The system for welding swings on platforms from Zbtk is a highly developed machine that was made to improve the efficiency and quality of welds. It does this through the use of technology unique to swing welding systems, which ensures even heat distribution as well as joint strength and looks among other things. This method can be used with various metals such as stainless steel alloys or carbon steels along with aluminum ones too; it finds wide application in fields like mechanical engineering production facilities construction sites for pressure vessels pipelines among others.

Moreover, not only is Zbtk’s system easy to operate but also cheap in terms of maintenance making them suitable for all sizes companies since they require minimum expenses during their lifetime. In addition to enhancing automation levels during welding processes while reducing man power input required hence reducing injuries caused by work accidents due to human error omission or commission acts of negligence etcetera… Therefore when one chooses the swing welding Application Program Interface (API) created by Zbtk, they are guaranteed good results because this is a reliable partner in production whose objective is customer satisfaction.

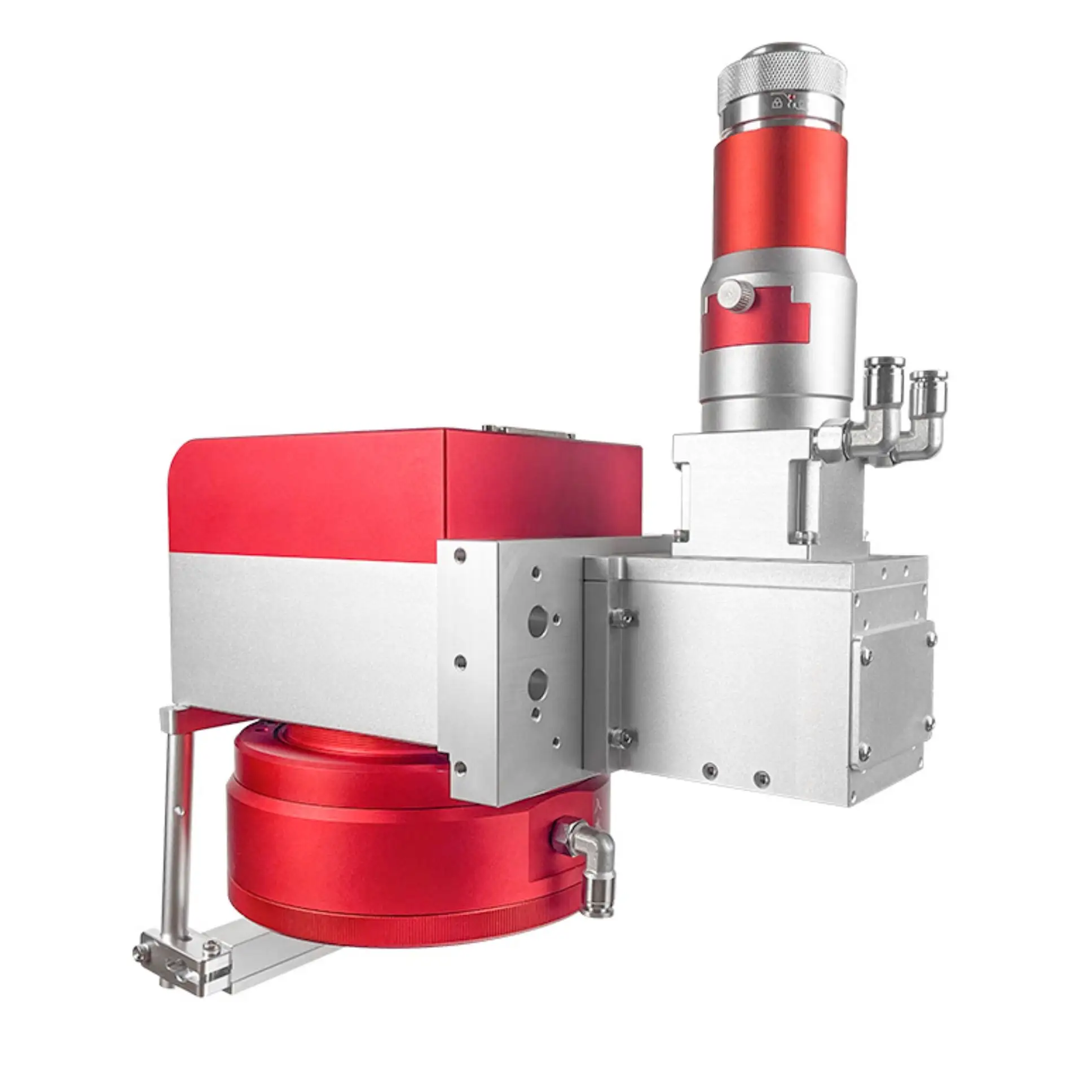

Ultra-fast scanning for bulk marking.

Portable power for on-site marking.

Eco-safe rust removal for bulk cleaning.

Durable, precise marking for volume production.

Zbtk's platform swing welding is a specialized welding method that utilizes a platform with a swinging motion to evenly distribute heat and create a consistent weld bead. The process involves positioning the workpiece on the platform, which then swings back and forth under the welding torch, ensuring a uniform weld and reducing the likelihood of defects such as cold laps or incomplete fusion.

Zbtk's platform swing welding system is designed to weld a wide range of materials, including mild steel, stainless steel, aluminum, and other common metals. It is particularly effective at welding thick sections and large workpieces, as the swinging motion helps to distribute heat more evenly and prevent warping or distortion.

Yes, Zbtk's platform swing welding is an eco-friendly welding option. It uses less energy compared to traditional welding methods due to the even heat distribution, which also results in less smoke and fumes. Additionally, the system's design promotes better material utilization, reducing waste and scrap.

Compared to manual welding or other automated welding systems, Zbtk's platform swing welding offers several advantages. It is faster, more consistent, and requires less human intervention. The swinging motion of the platform provides a deeper and more uniform weld than can be achieved with simple stationary welding methods.

Absolutely. Zbtk is committed to ensuring that our clients can fully utilize our platform swing welding system. We offer comprehensive training on how to operate the system effectively and safely, as well as ongoing technical support to address any questions or issues that may arise. Our goal is to empower our clients to achieve optimal results with our swing welding technology.