The Zbtk Galvo Scanner is a game-changer for industries seeking to enhance efficiency and precision in their laser applications. Engineered with cutting-edge galvanometer technology, the Zbtk Galvo Scanner provides high-speed, accurate laser beam control, essential for tasks such as marking, engraving, and cutting. This advanced scanner is capable of delivering exceptional performance across a wide range of materials, including metals, plastics, and ceramics. Zbtk's Galvo Scanner stands out for its ability to execute complex patterns swiftly and accurately, significantly boosting production throughput while maintaining top-notch quality. The scanner's robust design ensures long-term reliability, even in demanding industrial environments. Integration with existing systems is seamless, thanks to the Zbtk Galvo Scanner's intuitive interface and compatibility with various software platforms. Zbtk's dedication to excellence ensures that their Galvo Scanners not only meet but exceed industry standards, providing businesses with a powerful tool to optimize their laser processing operations and stay ahead in a competitive market.

The Zbtk Galvo Scanners are well known for their accuracy and speed, which is why they are used in a variety of industries. These devices employ advanced galvanometer technology that lets users control laser beams with precision necessary for marking, engraving or cutting things finely. Accuracy is especially important in sectors like electronics manufacturing where everything has to be done according to plan; aviation industry that deals with complex designs while producing aircrafts or medical field creating instruments such as surgical tools among others. Complex patterns can be easily represented through Zbtk Galvo Scanners’ ability to handle them without any difficulty hence every detail being reproduced faithfully. This greatly improves production efficiency since large amounts of work can be completed within short periods due to fast scanning speeds exhibited by these machines thereby reducing total time taken during production while maintaining high quality levels at all times which is ideal for businesses with tight schedules in areas like mass manufacturing plants where many items need to go through various stages before they become final products ready for market. Zbtk Galvo Scanners are built strong enough to withstand tough conditions thereby giving consistent results over long hours of continuous use under hard environments. The company’s devotion towards new ideas combined with quality guarantees that its galvo scanners outperform other models available on the market making them popular choices among enterprises seeking ways of optimizing laser processing activities

Zbtk Galvo Scanners are so changeable that they can be used in many industries. These scanners can handle different materials such as metals, plastics and ceramics; therefore suiting automotive, aerospace or electronics among others. In order to get precise control over the laser beam and ensure accurate and repeatable results across various applications Zbtk Galvo Scanners use advanced galvanometer technology. Moreover, this flexibility also includes compatibility with different laser sources which allows for easy integration into current systems. Designed for durability in tough environments where reliability is paramount even under adverse conditions; Therefore they have been built robustly using high-quality components thus guaranteeing continuous operation ability without failure leading to down time which saves maintenance cost too. Every part of their galvo scanners reflects Zbtk’s commitment to innovation and quality hence businesses trust them when seeking ways of enhancing laser processing capabilities. The reason why today’s competitive industrial landscape favors reliability together with versatility offered by Zbtk Galvo Scanners cannot be ignored.

In laser applications, Zbtk Galvo Scanners use advanced galvanometer technology which is far better than other systems. This type of technology is needed for such tasks as engraving, cutting and marking where you have to be able to control the laser beam with accuracy. The reason why these features are called advanced on the Zbtk Galvo Scanner is because it can do high-speed scanning which is what allows complex designs to be processed quickly. When your industry requires top quality output along with efficiency being at its highest level this speediness combined with preciseness becomes a must have feature for any company or person working in that field. With user-friendly interfaces designed into them making integration easy with any current manufacturing setup businesses know they can trust Zbtk Galvo Scanners will work well alongside everything else they already use within their factories or workshops etcetera (User friendly interfaces were built so that people could easily use this machine). They are compatible with various software platforms therefore enabling quick and efficient upgrades of laser processing capabilities thus saving time while maximizing productivity levels throughout different areas across an organization.The strong construction ensures long life even when used non-stop under harsh conditions like never stopping 24/7 operations over years without breaking down once!. If there’s one thing I admire about ZBTK it would be their commitment towards excellence because every single scanner produced by them meets all required standards set within an industry plus more too – giving enterprises powerful tools capable of enhancing production processes greatly (This means that every device created by zbtk surpasses minimum quality requirements hence becoming very useful in many areas). Advanced Technology coupled together with precision and velocity combo makes zbkt galvoscan best choice ever made by me whenever I want my lasers optimized.

To make industrial laser applications more productive, Zbtk Galvo Scanners were created. For marking, engraving, or cutting functions, these scanners provide fast and accurate laser beam control through advanced galvanometer technology. In order to reduce mistakes and waste thereby increasing overall efficiency the laser is made to move accurately with every step taken by it courtesy of this new-fangledness embedded into zbtks galvo-scanners. The speed at which they work enables quick processing of complicated patterns thus greatly improving throughput rates; this kind of efficiency is very useful in automotive or electronics manufacturing where large quantities need to be produced within a short period. As production lines cannot afford to slow down while striving for high speeds therefore such devices as those manufactured by ZBT K should be considered priceless since apart from increasing output levels; still maintaining top-notch quality becomes possible through their usage too! Besides even if used continuously under demanding conditions robustly built units like those made by ZBT K are designed last longer without breaking down easily hence saving money otherwise spent on constant repairs. It’s true that no other brand can beat what zbtk offers because not only do they meet but exceed industry standards so businesses must have them for survival in fast-paced markets according to zbtk’s commitment towards excellence alongside performance indicators being met by all their products including galvanometer scanners which have become very popular among various players due its ability improve competitiveness within different sectors

Ultra-fast scanning for bulk marking.

Portable power for on-site marking.

Eco-safe rust removal for bulk cleaning.

Durable, precise marking for volume production.

The Zbtk Galvo Scanner is primarily used in industrial settings for applications such as laser marking, engraving, cutting, and welding. Its high speed and precision make it suitable for detailed and complex tasks, ensuring high-quality results in various manufacturing processes.

The advanced Galvanometer technology in the Zbtk Galvo Scanner ensures high precision and speed during operations. This technology allows for rapid movement of the laser beam with minimal distortion, providing accurate and consistent results even at high speeds, which is crucial for industrial applications.

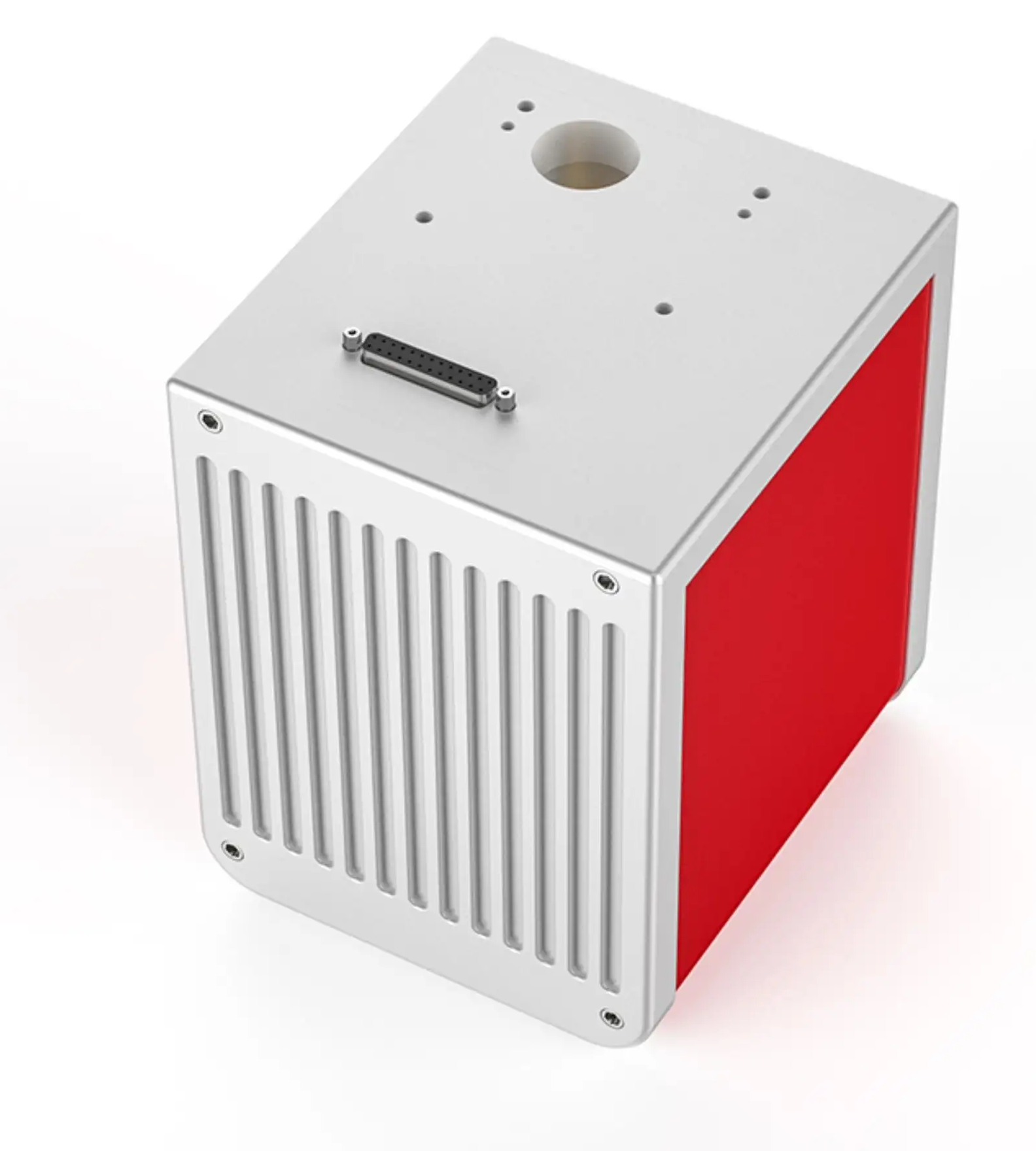

The Zbtk Galvo Scanner is designed for easy integration into existing production lines. Its compact and modular design allows it to be seamlessly added to current setups without requiring significant modifications. Additionally, Zbtk provides comprehensive support and customization options to ensure smooth integration.

Zbtk ensures the quality and reliability of its Galvo Scanners through rigorous quality control tests and adherence to high manufacturing standards. Each scanner undergoes extensive testing to verify its performance, durability, and precision, ensuring that it meets the specific needs of industrial clients.

Zbtk offers comprehensive technical support and maintenance services for its Galvo Scanners. This includes installation assistance, regular maintenance checks, troubleshooting support, and access to a team of experts who can provide prompt and effective solutions to any issues that may arise.