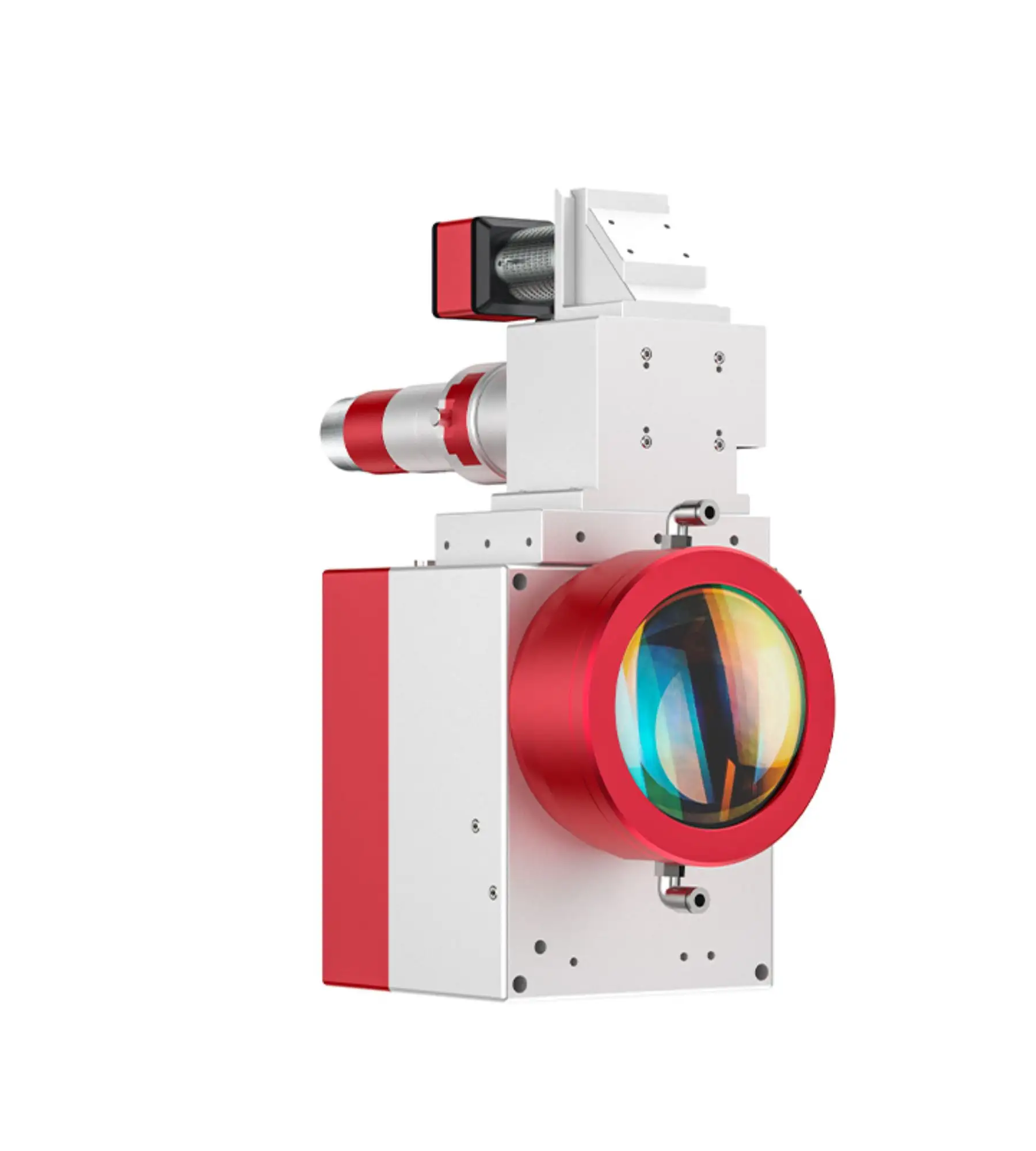

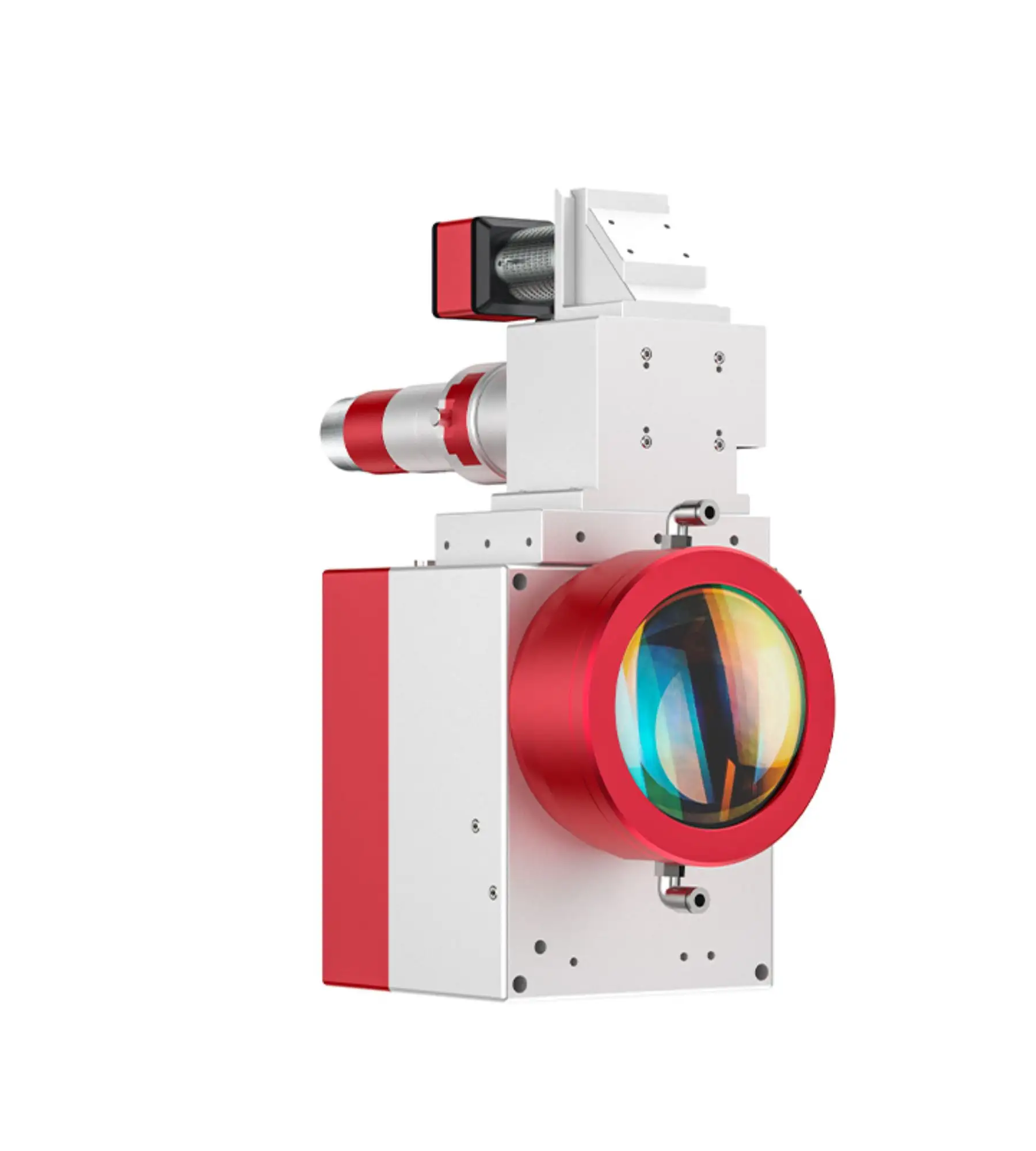

At Zbtk, we pride ourselves on delivering state-of-the-art galvanometer technology that pushes the boundaries of what's possible in laser applications. Our systems are meticulously designed to provide high-speed and precise control over laser beams, making them ideal for complex tasks such as 3D scanning, welding, and material processing. Zbtk's commitment to innovation means that our galvanometer technology is constantly evolving, incorporating the latest advancements to ensure you receive cutting-edge solutions. By integrating our galvanometer systems into your operations, you can significantly enhance your production capabilities, achieve higher accuracy, and reduce waste. Zbtk's technology is user-friendly and easy to integrate with existing systems, providing a seamless transition that minimizes downtime. Trust Zbtk to provide the galvanometer technology that drives your business forward, delivering results that exceed expectations.

Efficiency is important in the fast-moving industrial world of today. Zbtk’s galvanometer technology aims to optimize your laser processing operations by ensuring higher speed and greater control. Our galvanometer systems are built for high-speed functions without any compromise on precision which suits them well for 3D scanning among other applications like laser cutting and material processing too. Using Zbtk’s galvanometer technology will help you achieve the highest quality standards while cutting down processing time significantly. This increased productivity leads to lower operational costs thereby enabling organizations to do more within limited periods. The fact that our systems can be easily integrated into current workflows ensures minimal downtime during implementation hence making sure everything runs seamlessly. We are always updating our galvanometer technology with new features as part of being innovative so that we can keep pace with changes happening around us thus making it possible for one to stay ahead in their field through such advancements brought forth by Zbtk itself. When dealing with us at Zbtk, expect nothing short of a solution that serves not just your immediate requirements but also gets ready for tomorrow’s problems too.

Reliability is very important in every industrial application. The galvanometer technology of Zbtk is built for consistent performance that can be relied upon and trusted to keep any operation running smoothly and effectively. We have a laser beam positioning system which gives better control than any other in the market; this makes them most suitable for tasks needing high precision like laser marking, engraving or cutting. Zbtk has developed an industry-strength design capable of enduring harsh conditions common with industrial use thereby giving you something long-term reliable. This dependability comes from our belief in quality and innovation as well as always striving to remain ahead technologically among all manufacturers worldwide; thus if one chooses this brand then he/she should expect nothing less but only the best possible results every time without fail – simply put it’s worth every penny spent! What sets apart ZBTK’s galvo offerings from others on today's market? Well there are many answers but here are few: Firstly, these systems can be easily integrated into existing installations without causing much downtime hence ensuring smooth transitions while secondly they come with user-friendly interfaces making their operation quite easy even for newbies thus saving time during training sessions too. Finally, when dealing with such products made by zbtk one thing that should never worry anyone is performance or reliability because they always meet highest standards possible so no doubts here either! So give them a try now and see how much difference does it bring about in your working environment

In Zbtk, innovation is how they do galvanometer technology. We do everything possible and use new developments in our work. Our scanning systems are unmatched in terms of performance for different applications, such as cutting and engraving with a laser or welding and 3D scanning. By following the progress in this sphere Zbtk guarantees that precision and effectiveness of our goods will be the highest. It is this constant drive for progress which ensures that at all times our galvo-technology remains leaders among other producers thus providing necessary instruments for competitiveness. Flexibility is one of the key features to ZBTK design; therefore, they can easily fit into various workflows without any problems occurring which makes it suitable choice even more companies willing to increase their operational efficiency through better utilization of resources while still being cost effective where needed most – adaptability is something that really matters when it comes down to business process optimization which means that its application should be implemented at each stage so Trust us if you want stay up-to-date with what’s coming next

When it comes to laser applications, one cannot find a better technology for precision and speed than Zbtk’s galvanometer. Our systems are designed to satisfy the needs of different industries that is why they offer unprecedented command over positioning of laser beams thus guaranteeing maximum accuracy in each process. Such levels of accurateness are required especially during laser engraving, cutting, marking, or welding where even slightest deviation may spoil everything. At Zbtk quality is not something we take lightly hence our galvo techs are built strong enough to serve you longer while boosting efficiency at work too being reliable always. You will achieve shorter production cycles coupled with improved quality standards thereby reducing waste as well as saving on operational costs once you incorporate these devices into your workflow. The sturdiness exhibited by this kind of scan head makes it suitable even under unfavorable conditions encountered within industrial settings; therefore any enterprise can benefit from having one around its premises since they act as invaluable assets during such operations. What’s more? Continuous improvements made on galvanometers by ZBTK ensure that users like you have access to cutting-edge features which keep them ahead their rivals in markets where competition is rife. Should I say anything else? Just believe in us because nobody else does things better than we do them here!

Ultra-fast scanning for bulk marking.

Portable power for on-site marking.

Eco-safe rust removal for bulk cleaning.

Durable, precise marking for volume production.

Galvanometer technology involves the use of an electromechanical device called a galvanometer to control the angle of a laser beam with precision. The galvanometer contains a small mirror attached to a motor that moves in response to an electrical current. By adjusting the current, the angle of the mirror—and consequently the direction of the laser beam—can be precisely controlled. This allows for accurate and rapid positioning of the laser beam, making it ideal for applications such as laser engraving, cutting, marking, and medical procedures.

The primary advantages of galvanometer technology in industrial applications include:

In the medical field, galvanometer technology offers several benefits:

Galvanometer technology is compatible with a wide range of laser types, including:

When integrating galvanometer technology into existing systems, consider the following: