In the last ten years, the effectiveness and accuracy of laser processing technology seems to be growing closer to being an industry-standard for many sectors which include manufacturing, electronics, automotive, etc. One of the major elements determined accuracy level for laser processing is powered foe galvanometer-driven Laser. These devices allow the laser beam location to be performed quickly and efficiently, thus forming an integral function in laser systems design altogether. Companies like Zbtk have focused their attention on advancing information systems in terms of the design of galvanometer technology to improve operational laser efficiency.

Galvanometer Technology Explanation

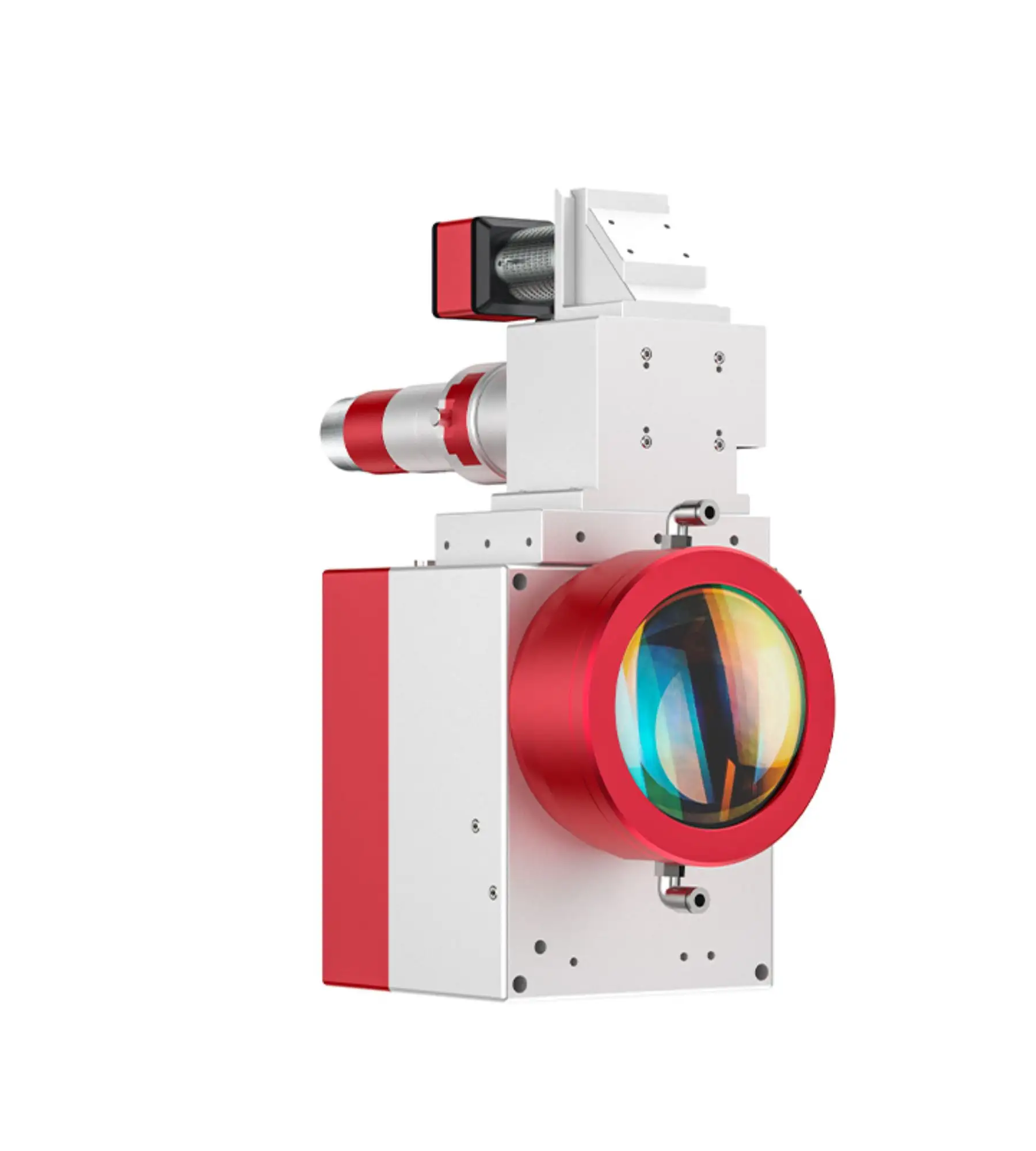

The galvanometer is an electromagnetically driven device that comprises a coil situated in the magnetic field, which is utilized to locate as well as regulate the position of the laser beam. During laser processing, galvanometers are used in laser beam delivery systems as beam steeper allowing the laser light to focus on a part of a workpiece in a fast and accurate manner. It’s a usual occurrence that the galvanostatic system possesses a mirror rotating along with a coil, which together moves according to an angle that makes an alteration in the direction of the laser beam.

Daunting Effects of the Laser Processing Misalignment

In the context of laser systems, the performance is proportionally dependent on the accuracy of the galvanometer which ranges from how quickly it can rotate along an axis, how fast it can pivot or it’s level of equilibrium. The response time for the laser focusing and pointing the beam on a spot is of paramount importance in engraving or cutting operations. Hence, utilizing a galvanometer would make it possible to decrease errors and produce consistent results for intricate processes.

Zbtk's position in the laser field gives the company the opportunity to offer galvanometer systems with significantly improved performance for rotary scanning with very low mechanical distortion. Zbtk’s galvanometer systems can be efficiently employed without losing focus even when moving fast and the laser process for complex designs and delicate materials is not hindered.

Used within Many Varieties of Applications

However, the galvanometric control of processes finds its usefulness in areas such as electronics, automotive and medical device industries that require high clear-cut edges with precision Otherwise, control systems could also improve process tolerances and reduce variability and wastage of products.

Final Thoughts

The technology of precise galvanometers is vital in improving the accuracy of laser steering in the process of laser beams assembly. Thanks to companies like Zbtk, to steer laser beams has never been so easy, and so precise! Such processes of high-speed and high-precision manufacturing can only increase demand and will give an increasing role for galvanometer-type systems for laser processing in the future which would also improve the speed, quality, and efficiency of operations.

Hot News

Hot News